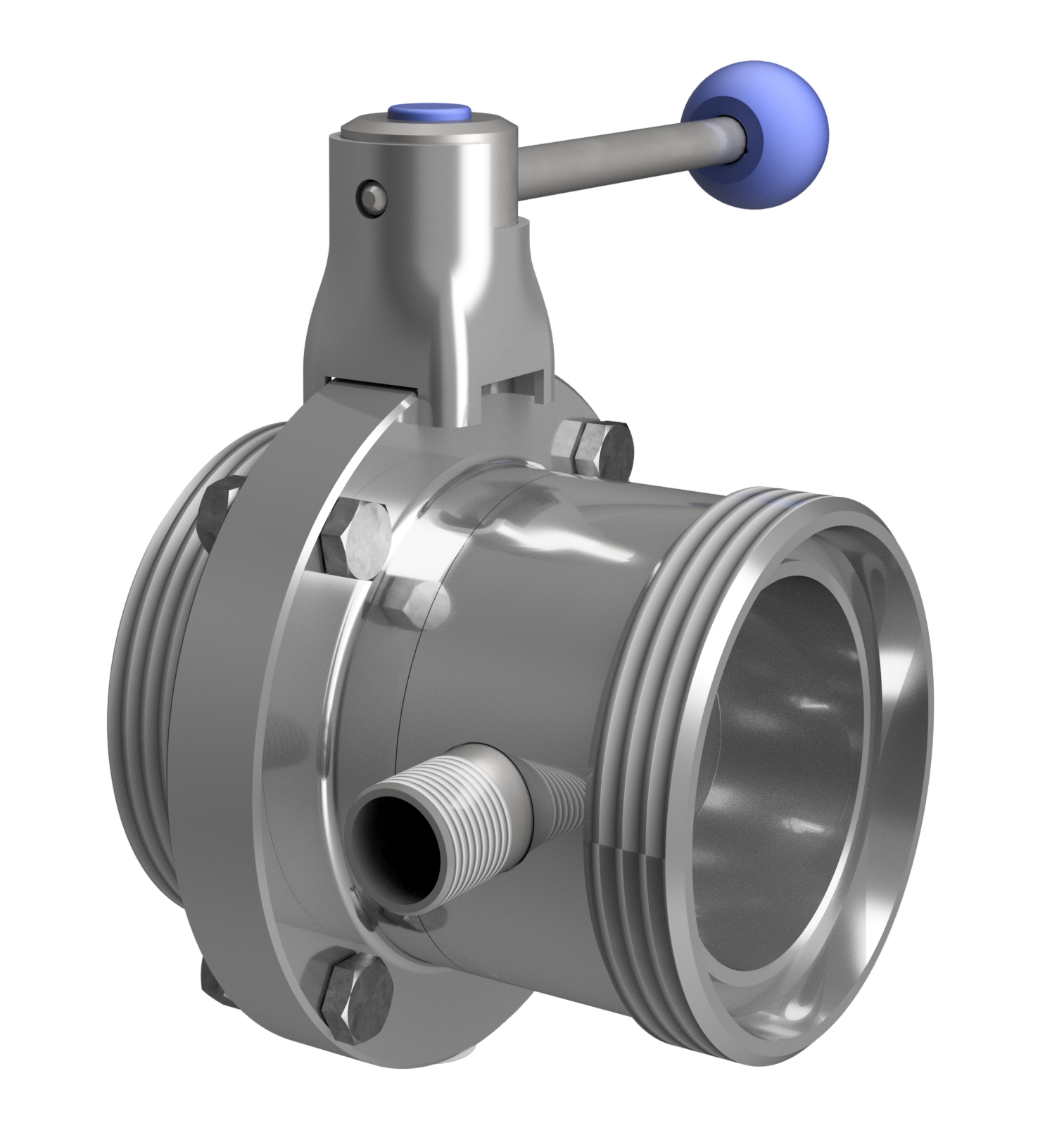

Butterfly Valve

AWH manufactures butterfly valves of the highest quality. Standard butterfly valves, compact intermediate flange butterfly valves and leakage butterfly valves are ideal for reliable media separation thanks to their outstanding design.

Butterfly Valve

The AWH butterfly valve has undergone continuous further development over the years. New, improved sealing materials are now used and tolerances have been narrowed further due to the ever-increasing temperature ranges. The AWH butterfly valve is available in various pipe standards and connection variations. Customer-specific designs can be realized thanks to our flexible production control.

The Heated Butterfly Valve

Highly viscous media that are kept flowable by temperature control are often a challenge for operators. Heated fittings and pipe components are therefore widely used in the food, bio-pharmaceutical, confectionery and cosmetics industries. The butterfly valves equipped with a double jacket are not only used for heating - they can also be used for cooling.

The new AWH butterfly valve series enables flanges with different connection variants to be combined using the modular system. Whether it is sufficient to heat on one side only or whether heating is required on both sides is up to the operator. Existing valves can also be supplemented with a heatable flange. The design offers the greatest possible heat input into the valve and therefore also into the medium to be heated.

The Compact Intermediate Flange Butterfly Valve

AWH also offers a compact intermediate flange butterfly valve with a hygienic design. The design impresses with its ease of servicing and compact installation dimensions. The design is based on the highest possible hygienic standards and easy cleaning. The flush-mounted flanges enable efficient cleaning. The O-rings installed inside ensure maximum hygiene in the interior. This is screwed to the valve body with two O-ring sealed flanges.

In addition, screws and threads are largely located in the housing. As a result, they are optimally protected against contamination in "open" production processes. Installation of the compact intermediate flange butterfly valve with a VMove® actuator is extremely simple thanks to the new AWH mounting bracket. This enables quick and precise installation. This means that the valve can be securely attached even in hard-to-reach places.

The Leakage Butterfly Valve

AWH relies on leakage butterfly valves with pneumatic auxiliary valves for hygienic and safe media separation.

The standard version of the design already consists of a leakage valve and a flush valve. Both can be controlled pneumatically synchronously or separately.

Cleaning the valves is comparatively simple and efficient due to their design. The valves are completely insulated when closed. The valve closing pistons are almost flush with the flow pipe. This means that no contamination can occur at this point.

The double flap principle guarantees the greatest possible safety of media separation in your pipe system.

Only high-quality AWH standard butterfly valve seals are used in the leakage butterfly valve.

In addition, the auxiliary valves have a connection piece with a 3/8" external thread. This allows them to be easily integrated into the corresponding pipe network.

There is also the option of retrofitting initiators to the actuator and auxiliary valves. These allow the individual valve positions to be monitored.